The Advent of Rapid Prototyping in China

In the ever-evolving world of manufacturing, rapid prototyping in China has established itself as a cornerstone of modern production methodologies. This innovative approach has transformed the traditional prototyping paradigm, enabling businesses to design, create, and refine their products with unprecedented speed and accuracy. The game-changing capabilities of rapid prototyping are making waves in various industries, including automotive, aerospace, consumer goods, and electronics. This article delves into the intricacies of rapid prototyping, its benefits, techniques, and its paramount significance in the realm of metal fabricators.

Understanding Rapid Prototyping

At its core, rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using 3D computer-aided design (CAD) data. These processes (often collectively referred to as 3D printing) allow producers to make physical parts from various materials in a fraction of the time it would take using traditional fabrication methods.

Key Techniques in Rapid Prototyping

Several techniques are central to rapid prototyping, and while each has its unique advantages, they all converge on the same goal: to bring a product from concept to reality swiftly. Prominent methods include:

- Stereolithography (SLA): A 3D printing technology that utilizes a laser to cure liquid resin into hardened plastic. It provides excellent detail and finish quality.

- Selective Laser Sintering (SLS): Utilizes a laser to sinter powdered material, binding it together to create a solid structure. Ideal for functional prototypes.

- Fused Deposition Modeling (FDM): A popular, cost-effective 3D printing method that extrudes thermoplastic filament layer by layer to create an object.

- Digital Light Processing (DLP): Similar to SLA, but uses a digital light projector to flash an image of each layer onto the resin, thus curing it rapidly.

- Metal 3D Printing: This method is becoming increasingly popular among metal fabricators and involves direct metal laser sintering (DMLS) to create complex metal parts, including titanium and aluminum.

The Impact of Rapid Prototyping on the Manufacturing Industry

Rapid prototyping has revolutionized how companies approach product design and manufacturing. The advantages include:

1. Speed and Efficiency

The hallmark of rapid prototyping is its incredible speed. What once took weeks or months to bring to market can now be accomplished in days. This acceleration allows businesses to stay ahead of the competition and respond swiftly to market demands.

2. Cost-Effectiveness

By using rapid prototyping, businesses can reduce costs associated with traditional prototyping methods. With fewer materials wasted and fewer resources consumed, companies can allocate their budgets more effectively, optimizing their operational expenses.

3. Design Flexibility

Rapid prototyping enhances design flexibility, enabling teams to iterate on their designs without significant financial or time constraints. This ability to quickly modify designs leads to improved products that better meet consumer needs.

4. Enhanced Communication and Collaboration

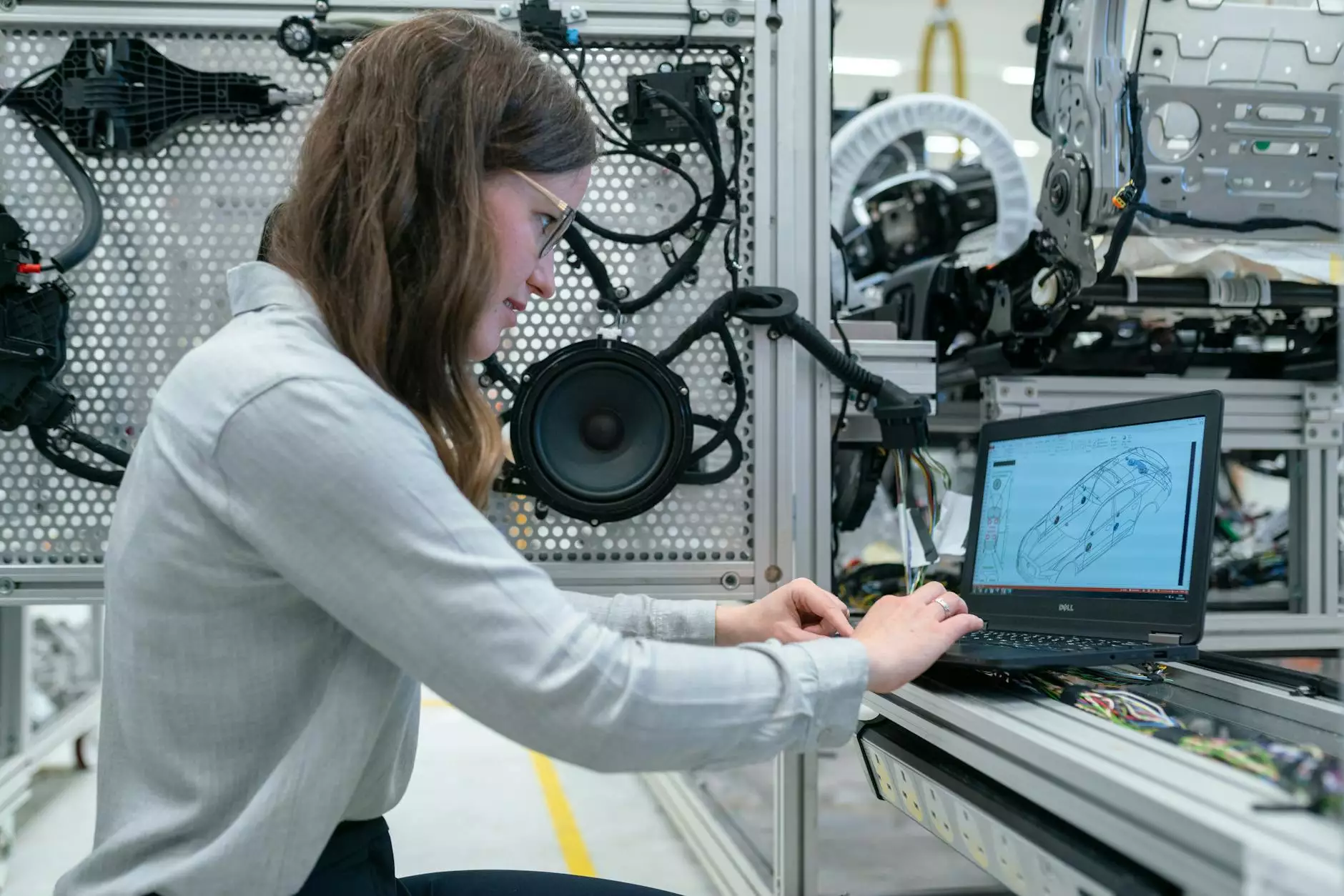

Having a physical prototype allows for better communication among stakeholders. Teams can collaborate effectively by evaluating tangible models rather than abstract drawings or digital representations, streamlining the feedback process.

Rapid Prototyping in China: A Growing Trend

China has emerged as a global leader in the field of rapid prototyping, driven by its robust manufacturing ecosystem and technological advancements. The country’s metal fabricators are increasingly adopting these innovative techniques to enhance their offerings.

Why China? The Competitive Edge

Several factors contribute to China's leadership in rapid prototyping:

- Investment in Technology: China's continuous investment in advanced manufacturing technologies fosters a conducive environment for rapid prototyping.

- Skilled Workforce: A large pool of engineering talent ensures that businesses can leverage cutting-edge techniques effectively.

- Supply Chain Efficiency: A well-developed infrastructure allows for seamless production and logistics, significantly increasing turnaround times.

- Cost Advantage: Competitive labor costs make prototyping affordable without compromising quality.

Case Studies: Successful Implementation of Rapid Prototyping

To better understand the transformative power of rapid prototyping, let's explore a few case studies from companies at the forefront of this technology in China.

Case Study 1: Automotive Components

A leading automotive supplier in China utilized rapid prototyping to develop a new engine component. By employing SLS technology, the company reduced the prototyping time from eight weeks to merely two weeks. This drastic improvement allowed them to proceed with production faster, ultimately leading to increased market share and revenue.

Case Study 2: Consumer Electronics

A consumer electronics brand was struggling with the design phase of a new smartphone model. They incorporated rapid prototyping to create multiple iterations of their design, benefiting from user feedback more rapidly. The result was a significantly improved product that generated positive consumer reviews upon launch.

The Role of Deep Mould in the Future of Rapid Prototyping

Deep Mould has positioned itself as a significant player in the realm of rapid prototyping within China. As an industry leader in metal fabricators, they leverage advanced technologies and methodologies to meet the needs of diverse sectors. Their commitment to quality and innovation sets them apart in a competitive landscape.

What Deep Mould Offers

Deep Mould provides comprehensive solutions that encompass the entire lifecycle of product development:

- Custom Prototyping: They offer tailored prototyping solutions that cater to the specific requirements of clients, ensuring maximum satisfaction.

- Material Expertise: With a deep understanding of materials, Deep Mould can recommend the best options for each project.

- High Precision: Utilizing the latest technologies, they guarantee high precision in all their prototypes, which is crucial for functional testing.

- Collaborative Development: The company fosters collaborative relationships with clients, involving them in the prototyping process to enhance outcomes.

Future Trends in Rapid Prototyping

The future of rapid prototyping in China looks promising as new technologies and methodologies emerge. Expect to see:

1. Increased Adoption of Automation

As automation technologies advance, the prototyping process will become even more efficient, reducing human error and further decreasing lead times.

2. Enhanced Material Diversity

New materials are being introduced, expanding the possibilities for prototyping. From advanced polymers to metal composites, innovators are continually pushing the envelope.

3. Integration of AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) will play critical roles in optimizing designs and predicting issues, making rapid prototyping smarter and more intuitive.

4. Sustainable Practices

As global focus shifts to sustainability, the rapid prototyping industry is also moving toward eco-friendly materials and processes, ensuring reduced environmental impact.

Conclusion: The New Era of Manufacturing

In conclusion, rapid prototyping in China is not just a trend; it is a powerful shift in how products are designed and manufactured. With the benefits of speed, cost-effectiveness, design flexibility, and enhanced collaboration, businesses are well-positioned to thrive in this new era of manufacturing. Companies like Deep Mould exemplify the potential of rapid prototyping, driving innovation and efficiency within the metal fabricators sector. As we move forward, embracing these advancements will be crucial for staying competitive in a global market.